Introduction: The Unseen Heroes of Modern MachineryWhen you pour a gallon of engine oil into your car or pump hydraulic fluid into an industrial machine, you're not just using a simple, slick

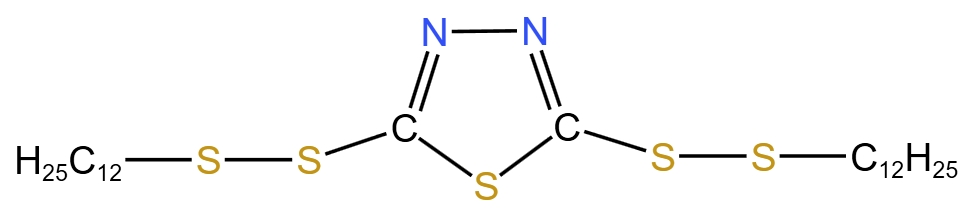

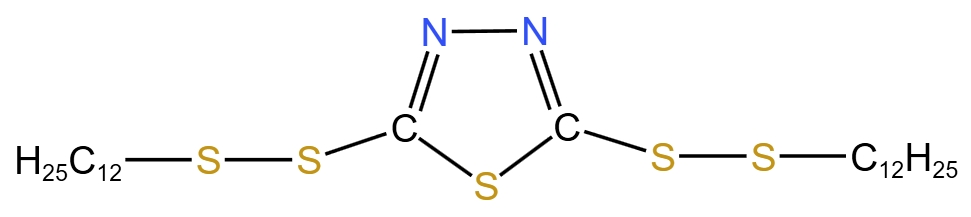

2,5-Bis(tert-dodecyl disulfanyl)-1,3,4-thiadiazole is an organosulfur compound belonging to the family of 1,3,4-thiadiazole derivatives.

mong the most effective solutions to this problem is a class of chemicals known as thiadiazole derivatives. One prominent example, Thiadiazole Derivative T561(CAS 59656-20-1), has emerged as a superio

Progress in the Application of Pour Point Depressants for Transporting Waxy Crude Oil via Pipelines-

Paraffin inhibitors are chemical additives widely used in the petroleum industry to prevent or mitigate the formation and deposition of paraffin waxes in crude oil and refined products such as diesel.

A corrosion inhibitor, in the context of oilfield applications, is a specialized chemical substance or formulation designed to significantly reduce the rate of electrochemical degradation of metallic

Demulsifier is a specialized chemical agent used to break down stubborn water-in-crude oil emulsions that form during petroleum extraction. It works by destabilizing the interfacial film surrounding w

Thiadiazole Derivatives are a class of highly effective organic metal deactivators. Their primary function is to inhibit the catalytic effect of metal ions (especially copper ions) on the oxidation of

Thiadiazole derivative T561 is far more than a simple metal deactivator. It is a sophisticated, multi-functional additive whose clever molecular design provides a robust and multi-faceted defense mech

n the complex and multifaceted realm of petroleum production, the formation of highly stable emulsions represents a significant and persistent operational challenge. These emulsions, which typically m

Crude oil demulsifiers are specialized chemical agents engineered to destabilize water-in-oil (W/O) or oil-in-water (O/W) emulsions, enabling efficient phase separation during oilfield production. The

Demulsifiers are specialized chemical agents designed to break crude oil emulsions by destabilizing the interfacial film formed around water droplets, thereby facilitating the separation of water from

Resin Oxyalkylate Demulsifier DEMET C-168: An Efficient Solution for Crude Oil Desalting and Dehydration

A crude oil demulsifier is a specialized chemical formulation designed to separate emulsified water from crude oil, a critical challenge faced during the crude oil production and refining process.