Thiadiazole dimer - a high-quality special grease additive

What is thiadiazole dimer?

As a semi-solid lubricating material, grease is widely used in the lubrication and protection of mechanical equipment. In order to improve the performance of grease, the use of additives is essential. Thiadiazole dimer (Thiadiazole Dimer), as a high-efficiency grease additive, has attracted much attention due to its excellent extreme pressure anti-wear performance, antioxidant performance and anti-corrosion performance.

Chemical structure and characteristics of thiadiazole dimer

1. Chemical structure

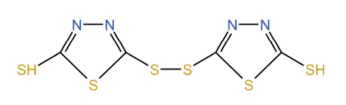

Thiadiazole dimer (chemical name: bis (dimercapto-1,3,4-thiadiazole), English name: Bis (dimercapto-1,3,4-thiadiazole)), is a sulfur and nitrogen-containing heterocyclic compound with a chemical formula of C4H2N4S6 and a molecular weight of 298.48. It usually exists in the form of a yellow powder with a high sulfur content (about 63.0%) and a nitrogen content (about 18.0%), and a melting point of about 160°C. Its molecular structure is as follows:

The molecular structure contains a dimer structure formed by two thiadiazole rings connected by a carbon-carbon bond. This unique structure gives thiadiazole dimer excellent chemical stability and reactivity.

2. Physical and chemical properties

Melting point: The melting point of thiadiazole dimer is relatively high, usually above 200°C, and is suitable for use in high temperature environments.

Solubility: It has good solubility in most organic solvents and is easy to add to grease.

Thermal stability: It is not easy to decompose at high temperatures and can maintain stable chemical properties.

Mechanism of action and performance characteristics of thiadiazole dimer

1. Extreme pressure and anti-wear properties

Thiadiazole dimer exhibits excellent extreme pressure and anti-wear properties in grease. The sulfur and nitrogen atoms in its molecules can react chemically with the metal surface to form a protective film, thereby reducing the wear of the metal surface. In the four-ball test, grease containing thiadiazole dimer can obtain a sintering load of 500-800 kg, showing its excellent load-bearing capacity. In addition, the anti-wear performance of grease can be further improved by compounding with other additives such as molybdenum dialkyl dithiocarbamate.

2. Antioxidant performance

Thiadiazole dimer has good antioxidant properties, which can effectively inhibit the oxidation reaction of grease under high temperature conditions and extend the service life of grease. This antioxidant property enables the grease to maintain good performance under extreme conditions such as high temperature and high pressure, reducing the deterioration of grease caused by oxidation.

3. Anticorrosion performance

Thiadiazole dimer also exhibits good anticorrosion performance in grease. The disulfide bonds in its molecules can break in a corrosive environment, releasing substances with corrosion inhibition, thereby protecting the metal surface from corrosion. Studies have shown that thiadiazole dimer can form a strong protective film on the metal surface, greatly improving the corrosion inhibition performance of grease.

4. Ash-free

Thiadiazole dimer does not contain metal components, so it will not produce ash during use, which helps to keep the lubrication system clean. This feature prevents the grease from affecting the lubrication effect due to ash accumulation during use, reducing wear and failure caused by ash.

5. Thermal stability

Thiadiazole dimer has a high melting point (about 160°C) and can remain stable under high temperature conditions. This thermal stability allows the grease to maintain good performance under high temperature conditions and reduce the failure of the grease caused by high temperature.

6. Compounding performance

Thiadiazole dimer can be compounded with a variety of other additives to form a synergistic effect and further improve the performance of the grease. For example, after compounding with dialkyl dithiocarbamate molybdenum, it shows good synergistic effects in extreme pressure and corrosion inhibition. In addition, after compounding with dialkyl dithiophosphate zinc and dialkyl dithiophosphate molybdenum, it also shows good synergistic effects in extreme pressure, anti-wear and corrosion inhibition.

Application of thiadiazole dimer

1. Lubrication field

Grease additives: Thiadiazole dimer is widely used in grease, especially in occasions where high extreme pressure performance is required, such as grease for steel mills and heavy-duty equipment. A four-ball sintering load of 500-800 kg can be obtained in the grease without causing corrosion to the copper sheet.

Lubricant additives: In lubricants, thiadiazole dimers can provide extreme pressure, anti-wear, antioxidant and anti-corrosion properties, and are suitable for various industrial lubricants.

2. Rubber industry

Rubber vulcanization accelerator: Thiadiazole dimers can be used as rubber vulcanization accelerators to accelerate the vulcanization process of rubber and improve the performance of rubber products.

3. Electronic materials

Near-infrared electroluminescent materials: Cyclic oligomers based on thiadiazole have potential applications in the field of organic optoelectronics, such as near-infrared electroluminescent materials.

4. Pharmaceutical field

Drug intermediates: Thiadiazole and its derivatives have a wide range of applications in the pharmaceutical field, and are used as drug intermediates to synthesize a variety of antibacterial, anti-inflammatory and anticancer drugs.

Thiadiazole Dimers Supplier

UNPChemicals is a professional and trusted grease additives supplier manufacturing high quality and range of grease additive according to your workflows and products. If you are looking for high performance grease additive solution, feel free to contact us.

Thiadiazole dimer EPSAIL® 8290 is a high-performance additive that delivers exceptional extreme pressure performance and outstanding anti-wear and anti-oxidation properties when dispersed in lubricating greases. With applications that span steel plants and heavy load equipment to various high-pressure lubricating greases, It can also be used as a rubber vulcanization accelerator. EPSAIL® 8290 plays a pivotal role in promoting equipment longevity, reliability, and overall efficiency.

Product name: EPSAIL® 8290

Chemical name: Thiadiazole dimer

Appearance: Yellow powder

Fusion point (%): ≥200

Sulfur content (%): 19.7 Nitrogen content (%): 12.0

Fineness, through 100 mesh (%): 99.9