Special lubricant additives - organic molybdenum (2)

What are organic molybdenum special lubricant additives?

Organic molybdenum special lubricant additives are organic compounds containing molybdenum elements. They have excellent friction improvement, anti-wear, extreme pressure and antioxidant properties and are widely used in a variety of lubricant products such as internal combustion engine oil, industrial oil, and grease. Its main function is to reduce the friction coefficient, reduce wear, and improve mechanical efficiency and life by forming a protective film on the metal surface. This protective film is composed of components such as FeS, MoS₂ and MoO₂, and has a solid lubricating effect.

There are many types of organic molybdenum additives, the most common of which include dialkyl dithiophosphate molybdenum (MoDTP), dialkyl dithiocarbamate molybdenum (MoDTC), etc. These compounds perform well under high temperature, high pressure and high load conditions, and can significantly improve the performance of lubricants. In addition, organic molybdenum additives also have good oil solubility, antioxidant and corrosion resistance, and can synergize with other additives in lubricants to further improve the overall performance.

Effect of the valence state of molybdenum in compounds on product color

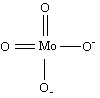

The oxidation state of molybdenum in compounds can be expressed as +2 to +6, among which the most stable oxidation state is +6. For example, in molybdenum trioxide, molybdic acid and ammonium molybdate, molybdenum appears in the form of hexavalent molybdenum, which is an important compound of molybdenum.

Molybdenum trioxide MoO3 is a white powder, which can be turned into yellow when heated.

When hydrochloric acid is added to ammonium molybdate solution, molybdic acid will precipitate:

(NH4)2MoO4+2 HCl=H2MoO4↓+2 NH4Cl

When molybdic acid is heated and roasted, it decomposes into MoO3:

H2MoO4=MoO3+ H2O

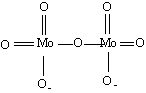

Although molybdenum trioxide is an acidic oxide, it is difficult to dissolve in water. Accordingly, one of the important characteristics of molybdic acid is that it has a very low solubility in water. The molybdenum-oxygen bond of the molybdate ion MoO42- is weak. Therefore, another important feature of molybdic acid is that it is easy to form polyacids (for example, the various sausage products we eat in our daily life contain sodium polyphosphate, which can increase the taste and appearance of the sausage and retain moisture), and the O2- ions in it are also easily replaced by other anions. For example, if the acidity of the molybdate solution is gradually reduced, the molybdate will gradually polymerize into a series of isopolyacids such as dimolybdate Mo2O72- and trimolybdate Mo3O103-, and finally precipitate MoO3.

In an acidic solution, only a strong reducing agent can reduce H2MoO4 to Mo3+. Concentrated hydrochloric acid is added to the (NH4)2MoO4 solution, and then it is reduced with metallic zinc. The solution is initially blue, then reduced to green MoCl5, and finally generates brown MoCl3:

2(NH4)2MoO4+3Zn+16HCl=2MoCl3+3ZnCl2+4NH4Cl+8H2O

Ammonium molybdate reacts with H2S in an acidic solution to precipitate brown molybdenum trisulfide:

(NH4)2MoO4+3 H2S+2 HCl=MoS3↓+2 NH4Cl+4H2O

Of course, since molybdates easily form polyacids, molybdenum compounds can also undergo more complex changes. For example, when the (NH4)2MoO4 solution acidified with nitric acid is heated to about 50°C and disodium hydrogen phosphate Na2HPO4 solution is added, a yellow crystalline precipitate of 12-ammonium phosphomolybdate can be generated:

12MoO42-+3NH4++HPO42-+23 H+=(NH4)3[P(Mo12O40)]﹒ 6 H2O+6 H2O

The reason why so much space is used to introduce the relevant knowledge of the inorganic chemistry of molybdenum is to remind colleagues that the organic molybdenum additives used in lubricating greases sometimes show different colors for no reason, such as dark green, brown red, etc. In fact, in the preparation of complex organic molybdenum additives, the reaction conditions cannot be very accurately controlled, and what can be obtained is often a mixture of different complex substances. Sometimes it is difficult to determine what factors make the additives show different colors due to the variability of the color of the molybdenum element itself. It is also very difficult to accurately explain these phenomena.

When it comes to color, especially the color of lubricating oil, some people seem to have a "complex". Some imported oils or water-based products, for different reasons, will add some pigments to present red, blue, green and other appearances. Some users appreciate it very much, and even require other suppliers to imitate these colors as standards. In fact, in my opinion, the main purpose of this practice of some imported products may be to cover up the ugliness - different batches of products, especially light-colored lubricating oils, cannot accurately control each batch to keep the color depth exactly the same. At this time, adding pigments to the oil will cover up this shortcoming that is not a shortcoming, and the addition of pigments is also because the amount added is so small that it is impossible to affect the performance of the product.

Generally speaking, the same model products under the same standard of different manufacturers should not have different performances due to different appearance colors. It is still the old saying: know the reason as well as the reason.

The proposition of the color of molybdenum compounds is mainly to illustrate the complexity of organic molybdenum additives. Often several active elements coexist in organic molybdenum additives, especially the molybdenum element, which can present different valence states and different colors in this complex mixture. But in the final analysis, the final molybdenum mainly appears on the friction surface in the form of molybdenum disulfide, with trivalent molybdenum and tetravalent molybdenum oxides in between. So in essence, the anti-wear and friction-reducing effect of organic molybdenum is dominated by layered molybdenum disulfide, and its friction-reducing effect is not affected by its color, because the difference in color is caused by the different valence states of molybdenum, but in the friction process, it will eventually return to molybdenum disulfide.

The following content can more clearly show that the color of organic molybdenum additives does not constitute a difference in their performance.

The so-called organic molybdenum is a general term for oil-soluble organic molybdenum compounds such as dialkyl dithiophosphoric acid oxygen molybdenum, dialkyl dithiocarbamate molybdenum, molybdenum amine complex, cyclohexane acid molybdenum, alkyl salicylic acid molybdenum.

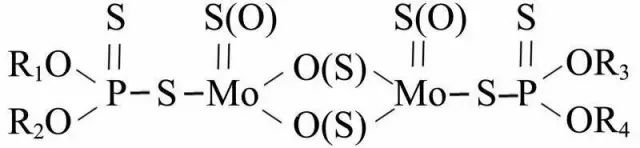

The different types of organic molybdenum have different raw materials and synthesis processes. For example, the synthesis process of dialkyl dithiophosphoric acid oxygen molybdenum, which is widely used on the market, can be simply described as:

1. Alcohol reacts with S and P compounds at 85-115℃ to generate organic thiophosphoric acid.

2. The generated organic thiophosphoric acid, in an acidic medium, under the action of a catalyst, the temperature is maintained in the range of 85-115℃, and reacts with complex hexavalent molybdenum to generate an organic molybdenum additive.

3. Add an extractant to the above-mentioned synthesized product, extract, wash, separate, and distill to obtain the finished product.

MoDDP

In fact, the above structural formula is just a schematic diagram. People often habitually call it MoDDP, called dialkyl dithiophosphate oxymolybdenum, sometimes also called sulfurized dialkyl dithiophosphate oxymolybdenum, and can also be called dialkyl dithiophosphate molybdenum. In fact, its true state is much more complicated.

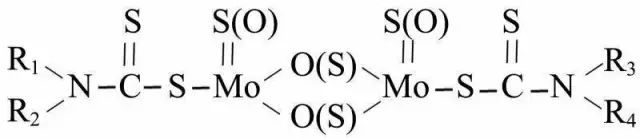

For example, the specific example of molybdenum dialkyl dithiocarbamate (MoDTC) is also a very complex compound, or more precisely, a mixture:

MoDTC

The mechanism of action of organic molybdenum is still under research and development, and there is no definite conclusion yet. Among the analytical methods for studying its friction behavior, scanning electron microscopy (SEM) and X-ray photoelectron spectroscopy (XPS) are more common. It is generally believed that Mo, S, P, etc. are enriched on the friction surface. Mo and S form films through chemical reactions, while P elements form films by deposition. FeS, MoS2, MoO2, FePO4, and FeMo2O4 can all be in the form of existing friction products.

UNPChemicals Organic Molybdenum Product Introduction

UNPChemicals is a leading domestic manufacturer of special lubricant additives established in 2014. UNPChemicals has a modern and standardized fine chemical production plant, and has passed ISO9001 quality management system certification and ISO14000 environmental management system certification. The company has an excellent R&D team, and its products are comparable to internationally renowned brands in terms of performance and quality. As the world's third manufacturer of oil-soluble organic molybdenum friction reducers, UNPChemicals takes "integrity first, technology-based" as its purpose, becoming a leader in the field of special lubricant additives, bringing high-quality and high-performance special lubricant additives to the world.

MSAIL® 525A:Molybdenum Dithiocarbamate (MoDTC) is a phosphate-free liquid organic molybdenum friction modifier, which can greatly reduce the friction coefficient of oil products, and has a variety of functions such as anti-wear and anti-oxygen, and is widely used in internal combustion engine oil, various industrial lubricants, pure oil-type metal working fluids, greases, etc.

Treat level: Lubricant: 0.2-3.0%

Chemical name: Molybdenum Dithiocarbamate (MoDTC)

Appearance: Brown-green liquid

Molybdenum content (%): 10

Sulphur content (%): 11

Nitrogen content (%): 1.5