Special lubricant additives - organic molybdenum (1)

What are organic molybdenum special lubricant additives?

Organomolybdenum is a special lubricant additive, mainly composed of molybdenum-containing organic compounds, with excellent anti-friction, anti-wear, anti-oxidation and extreme pressure properties. It can form a protective film on the metal surface, reduce the friction coefficient, reduce wear, while extending the service life of the lubricant and improving fuel economy. Organic molybdenum is widely used in internal combustion engine oil, industrial lubricant and metalworking fluid, especially in high temperature, high load and harsh working environment. With the improvement of environmental protection requirements, low sulfur, low phosphorus or even sulfur-free and phosphorus-free organic molybdenum additives (such as nitrogen-containing organic molybdenum) are becoming the future development trend, further promoting the development of the lubricant industry towards green and efficient direction.

The role of molybdenum in lubricating materials

Molybdenum, in the periodic table, belongs to the VIth group of the fifth period and is a "transition metal element". The outer electron layer configuration of its atoms is: 4d5 5s1, and the valence electron layer orbital is half-filled, between lithophile elements (8-electron ionconfiguration) and cuprophile elements (18-electron ion configuration), showing a typical transition state.

The so-called lithophile elements are those that have a strong affinity with oxygen and become oxides. They are components of rocks, so they are also called rock-forming elements; the so-called cuprophile elements are those that have a strong affinity with sulfur and are easy to form sulfides. For example, the main mineral of molybdenum is molybdenite, that is, molybdenum disulfide (MoS2).

Natural molybdenite MoS2 is a soft black mineral with an appearance very similar to graphite, so graphite and molybdenum disulfide can be used as solid lubricating materials and have considerable applications in the lubricating oil industry. If molybdenum disulfide is used in the manufacture of friction materials, its main function is to reduce friction at low temperatures and increase friction at high temperatures. Such properties just match what we want. In the resin materials that we can come into contact with in daily life, such as brake pads, automatic transmission friction belts, etc., are molybdenum disulfide also added? I need to ask experts in friction materials for advice.

Molybdenite has the largest reserves in Henan, accounting for about 30% of the total reserves of molybdenum ore in China. It is mainly distributed in Songxian and Luanchuan counties in Luoyang, adjacent to Yichuan and Ruyang. It belongs to the Funiu Mountain System and is beautiful. Therefore, it is not unreasonable for UNPChemicals, which is famous for its organic molybdenum additives, to set up its production plant there. Of course, colleagues who like to have a drink in their spare time must also know that "Dukang Wine" is from the same place of origin. I hope that UNPChemicals will fly side by side with "Dukang", and Pacific United's organic molybdenum will shine in the lubrication industry and live up to the name of "molybdenum".

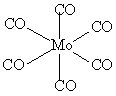

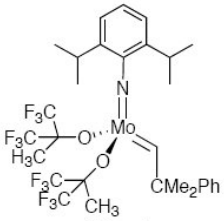

Let's get back to the topic. Since molybdenum has 4d and 5d orbitals involved in the reaction of bonding, the valence electron layer can accommodate 18 electrons. This is the so-called 18-electron rule of the molecular structure of transition metal organic compounds, that is: in transition metal complexes, when the sum of the number of outer electrons in the d orbital and the number of electrons provided by the ligand is 18, it is thermodynamically stable. For example, hexacarbonyl molybdenum and complex molybdenum complexes can form a σ bond or a π bond in terms of the bonding properties of molybdenum from a chemical point of view.

We call these compounds, as well as complexes connected by molybdenum-nitrogen and molybdenum-sulfur, metal organic compounds.

In general, the natural state of molybdenum is relatively stable, but it can also undergo chemical reactions at high temperatures:

2 MoS2+ 7 O2→ 2 MoO3+ 4 SO2

And molybdenum trioxide can be dissolved in ammonia water to form ammonium molybdate:

MoO3+2NH3·H2O→(NH4)2MoO4+H2O

MoS2→MoO3→(NH4)2MoO4→H2MoO4→MoO3

In this way, we can prepare a series of desired molybdenum compounds.

Environmental protection and energy saving are the consensus directions in the lubricant industry. The friction reduction effect of organic molybdenum will contribute to energy saving and environmental protection, so that its application in oil products will be gradually promoted. At present, internal combustion engine oil, gear oil, hydraulic oil, automatic transmission oil, metalworking oil, and organic molybdenum also have their uses. In the domestic market, UNPChemicals, Vanderbilt, and Rhein Chemie are undoubtedly the leaders of organic molybdenum.

UNPChemicals Organic Molybdenum Product Introduction

UNPChemicals is a leading domestic manufacturer of special lubricant additives established in 2014. UNPChemicals has a modern and standardized fine chemical production plant, and has passed ISO9001 quality management system certification and ISO14000 environmental management system certification. The company has an excellent R&D team, and its products are comparable to internationally renowned brands in terms of performance and quality. As the world's third manufacturer of oil-soluble organic molybdenum friction reducers, UNPChemicals takes "integrity first, technology-based" as its purpose, becoming a leader in the field of special lubricant additives, bringing high-quality and high-performance special lubricant additives to the world.

MSAIL® 300L: Molybdenum Dithiophosphate (MoDTP) as a liquid organic molybdenum friction modifier containing sulfur and phosphorus, it can greatly reduce the friction coefficient of oil products, and has multiple functions such as extreme pressure, anti-wear and anti-oxidation. It is widely used in internal-combustion engine oil, various industrial lubricants, pure oil metalworking fluid, grease, etc.

Treat level: Lubricant: 0.2-1.0%, Grease: 1.0-3.0%

Chemical name: Molybdenum dithiophosphate

Appearance: Brown liquid

Molybdenum content (%): 9.1

Sulfur content (%): 11.3

Phosphorus content (%): 3.2