Phosphorus-based extreme pressure anti-wear additives are the core of the entire lubricant additive film system

What is extreme pressure anti-wear agent?

Extreme pressure anti-wear agent is an additive used in lubricating oil or grease, mainly composed of organic polar compounds containing sulfur, phosphorus, chlorine, etc. It can react chemically with the metal surface under high pressure and high temperature to form a chemical reaction film, thereby effectively reducing the friction and wear of the metal surface. This film can prevent the metal surface from sintering, biting and scratching under high load conditions. Extreme pressure anti-wear agents are widely used in industrial lubricants and greases, such as steel, mining, electricity, automobiles and aviation. Its mechanism of action mainly includes chemical reaction principle, soft film principle, lubrication principle and surface cushion principle. Through these mechanisms, extreme pressure anti-wear agents can significantly improve the operating efficiency and service life of mechanical equipment.

Classification of extreme pressure anti-wear agents

It can be divided into two categories: sulfur-based extreme pressure anti-wear agents and phosphorus-based extreme pressure anti-wear agents.

Sulfur-based extreme pressure anti-wear agents

Characteristics: Sulfur-based extreme pressure anti-wear agents show excellent performance under high temperature or high load conditions. They can react chemically with the metal surface to form a sulfide film, such as iron sulfide film (FeS), which has a high melting point and good shear strength. Sulfur-based extreme pressure anti-wear agents usually have good oil solubility and anti-sintering ability.

Classification: Common sulfur-based extreme pressure anti-wear agents include sulfided olefins, sulfided oils, thioesters, thiocarbonates and polysulfides. Among them, sulfided olefins are the most widely used in practical applications due to their good anti-sintering and load resistance.

Phosphorus-based extreme pressure anti-wear agents

Characteristics: Phosphorus-based extreme pressure anti-wear agents mainly provide anti-wear properties by reacting with metal surfaces to form phosphate films. This type of additive exhibits good anti-wear properties under medium load conditions. However, the thermal stability of phosphorus-based extreme pressure anti-wear agents is relatively poor, and the anti-wear durability is not as good as that of sulfur-based ones.

Classification: Phosphorus-based extreme pressure anti-wear agents include phosphates, phosphites, acidic phosphate amine salts and thiophosphates. For example, tricresol phosphate and di-n-butyl phosphite are commonly used phosphorus-based extreme pressure anti-wear agents, which have good anti-wear performance and oil solubility.

Phosphorus-based extreme pressure anti-wear additives are the core of the entire lubricant additive film system

In practical applications, different types of extreme pressure anti-wear agents are usually mixed in a certain proportion to obtain better comprehensive performance.

In the field of extreme pressure anti-wear agents, sulfur seems to be very powerful, but sulfur is not really the core because of its corrosiveness.

The real core substance is the phosphorus element we are going to talk about today.

Let's put up a few pictures, as follows:

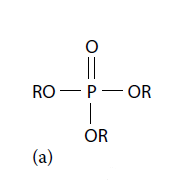

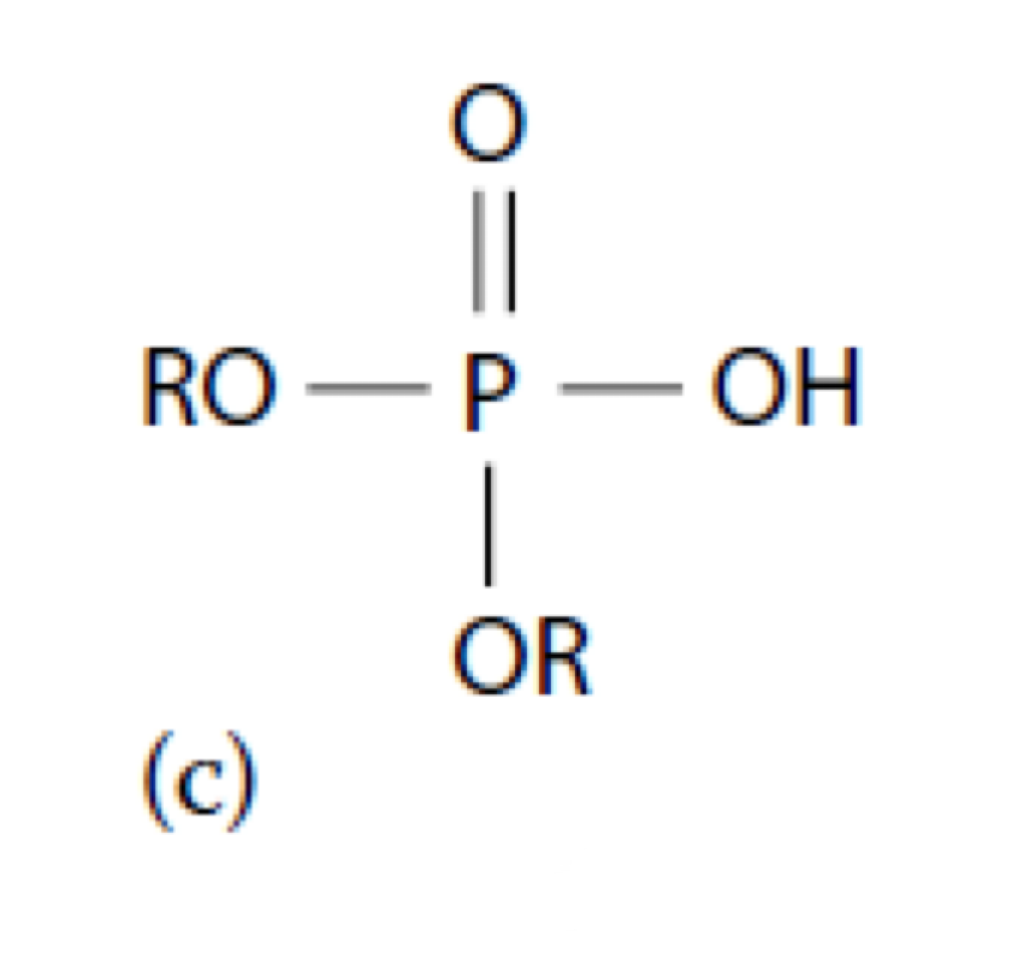

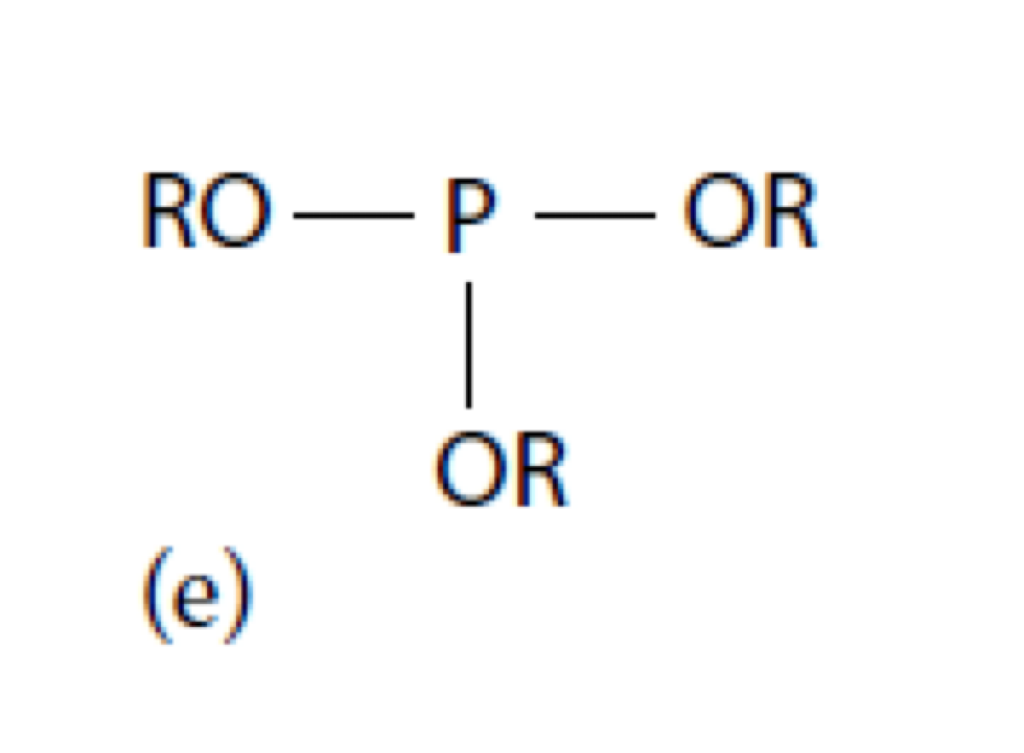

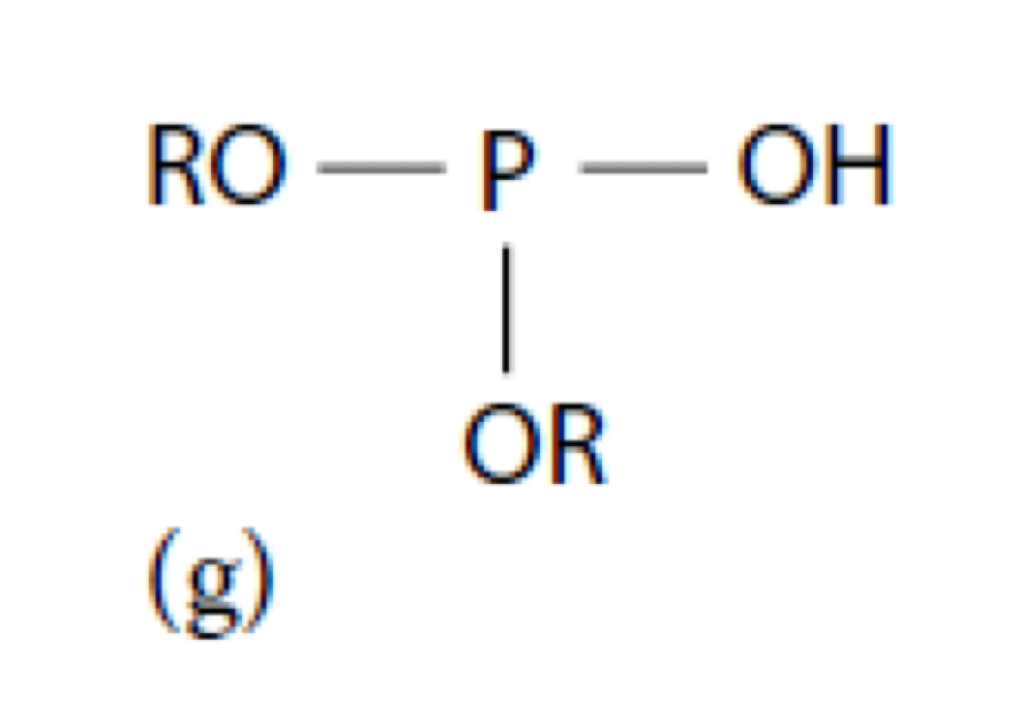

(a): Orthophosphate (c): Acidic phosphate

(e): Phosphite (g): Acidic phosphite

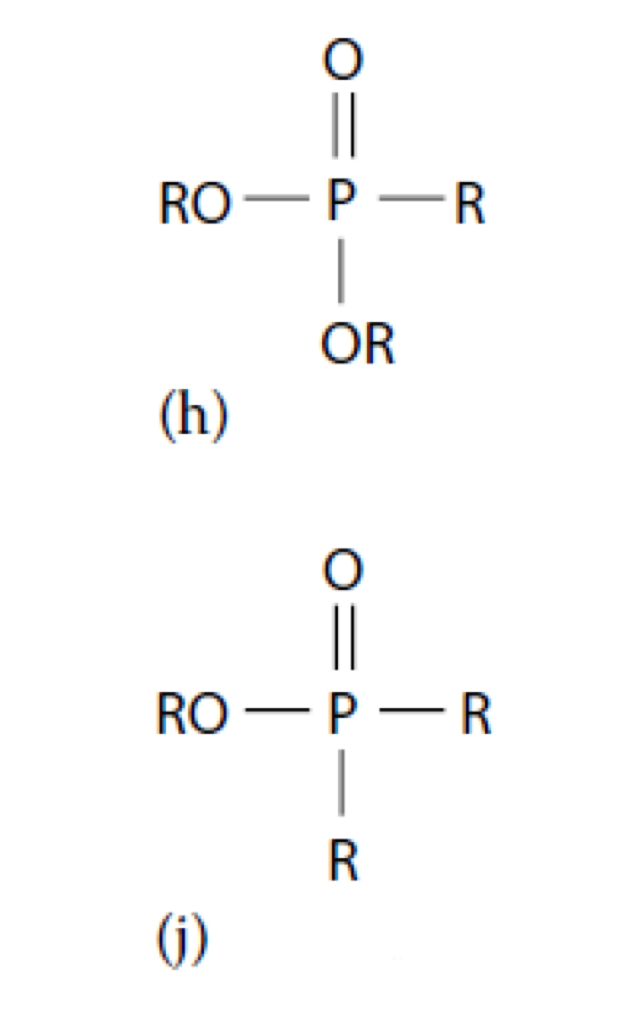

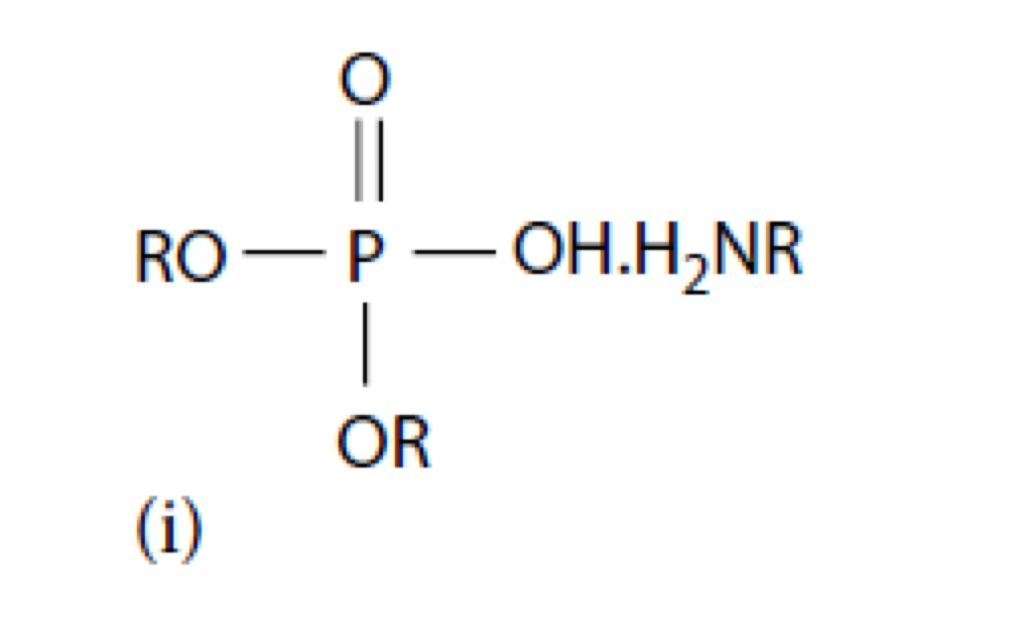

(h,j): Phosphonate (i): Acidic phosphate amine

When talking about sulfur in the previous article, there is a very interesting concept of activity. In the field of extreme pressure anti-wear agents, whether it is sulfur, phosphorus, or chlorine, it is actually membrane chemistry, which is to study that layer of membrane. As long as you study the membrane, you have to study the amphoteric. They are: adsorption degree (polarity) or reactivity (activity). The activity of sulfur mainly depends on the composition of sulfur elements in the main structure, not on its carrier, while P is completely different; due to the weak reaction of P, the phosphorus in the current phosphorus additive system is in the form of phosphate or phosphate ester. Please note that this is actually the core difference between P and S and Cl, that is, P is on the battlefield with oxygen, while S and Cl are fighting alone. Of course, this also depends on their own combat strength.

Compared with S, P is far less active than S, but if it is mixed with O, the outcome is uncertain. Some people say that S can also be used, of course, but the acidity of S+O is too strong. Various acidic compounds of S and O will react directly with metals. The reaction is thorough, not membrane chemistry, but thorough reaction. Phosphoric acid substances are much milder, and our extreme pressure agent is just this mild film, and anti-wear agents are even milder.

Therefore, phosphorus additives are the core of the entire lubricating additive film system. I am not wrong, there is no other. The most interesting thing is that the other one that joins forces with him happens to be the core of synthetic base oil, that's right, ester.

So, when the two of them are combined, they form a film; and the other S, N, B, Mo, etc. are all accessories.

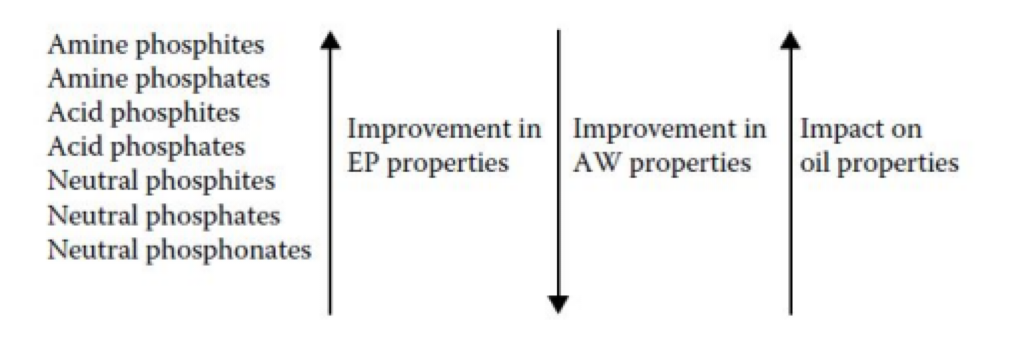

The activity of extreme pressure agents is opposite to that of anti-wear agents. This principle is the general outline of all anti-wear or extreme pressure additives. It depends on which side of the balance beam is tilted. And the same is true for P. Direct conclusion:

Extreme pressure: phosphite amine> phosphite amine> acid phosphite> acid phosphate> neutral phosphite> neutral phosphate> neutral phosphonate. The order of anti-wear is reversed.

Now everyone can understand the pictures I showed you at the beginning.

Let me explain the principle:

First, the first process is surface adsorption, that is, the additive seeks the friction pair surface and adsorbs onto it (the principle is through P=O and P-OH in the molecule, one is an ester bond and the other is an alcohol acid bond)

The second step is the hydrolysis of the ester. Any -P-OR will hydrolyze into -P-OH, and then phosphite or acid phosphate will appear.

Finally, one or both of this -P-OH or -P-(OH)2 reacts with the metal surface to form Fe salt, and then continues to hydrolyze until there is no R group. At this time, the new -P-OH will continue to react with the Fe surface and finally connect all -P-OH groups to form a solid layer of polyphosphate. -P-OH are hand in hand and attached to the metal surface. In general, the final film-forming substance is a solid layer of polyphosphate iron.

After looking at this principle and the order of the above figure, since all acid esters and phosphites start directly from the second step, the extreme pressure of acid esters and phosphites is higher than that of orthophosphate (also called neutral ester). But the anti-wear effect is just the opposite.

For the same neutral ester, since phosphonate contains fewer P-O bonds, the film will form more slowly and the extreme pressure effect is not good, but the anti-wear effect is good, which is why it is ranked last. Neutral phosphates have slightly better extreme pressure properties, followed by neutral phosphites.

Acidic esters are ranked in the same way, and acidic phosphites have better extreme pressure effects. Amines are at the top. The introduction of amines mainly introduces new adsorption functional groups, allowing these amine groups to be adsorbed in the small gaps of phosphates, allowing this film to form faster, denser, and stronger, which is equivalent to introducing another layer of film, so the extreme pressure properties will be better. The introduction of the amine salt part also gives amine phosphates typical rust resistance.

UNPChemicals has a wide range of phosphorus-based extreme pressure and anti-wear agents that can meet the application needs of customers under different working conditions:

Product Code | Composition | Specifications

| ||||

Appearance | Density (20℃,g/cm3) | Flash Point Open Cup (℃) | Phosphorus Content (%) | Nitrogen content (%) | ||

PSAIL 3661A/B | Tricresol phosphate (T306) | Colorless or light yellow transparent liquid | 1.17 | ≥230 | 8.4 | / |

PSAIL 3680 | Trioctyl phosphate | Colorless clear liquid | 0.92 | 174 | 7.0 | / |

PSAIL 3150 | Isopropyl phenyl phosphate | Colorless or light yellow transparent liquid | 1.17 | — | ≥8.3 | / |

PSAIL 3220 | T-butyl phenyl phosphate | Colorless clear liquid | 1.18 | — | 8.1 | / |

Amine-neutralized hexyl phosphate | Colorless to light yellow transparent liquid | 0.93 | 161 | 4.5 | 2.3 | |

PSAIL 3740 | Amine-neutralized butyl phosphate (T308) | Yellow viscous liquid | 0.97 | 150 | 9.0 | 3.8 |

PSAIL 3741 | Amine-neutralized butyl phosphate | Yellow transparent liquid | 0.96 | 140 | 7.4 | 3.2 |

Amine-neutralized mixed phosphate esters | Yellow transparent liquid | 0.96 | 121 | 7.8 | 2.4 | |

Professional Lubricant Additive Manufacturer

UNPChemicals, aka Luoyang Pacific United Petrochemical Co., Ltd., focuses on the application and development of special lubricating grease additives such as MoDTC, MoDTP, molybdenum amide, thiadiazole metal deactivators, and phosphate esters. With nearly 30 products in seven series, including extreme pressure anti-wear agents and special grease additives, it is a global manufacturer of special lubricating grease additives and a national high-tech enterprise with great influence and leading role in the industry.