Oil-soluble organic molybdenum additives - the older they get, the more spirited they are, with a journey of nearly 70 years!

What are oil-soluble organic molybdenum additives?

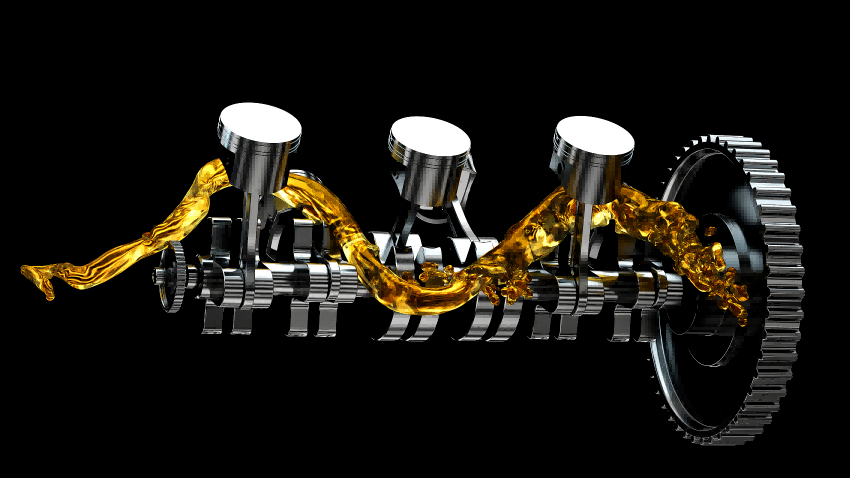

Oil-soluble organic molybdenum additives are a class of organic compounds containing molybdenum elements and capable of dissolving in lubricating oils. They generally have excellent anti-friction and anti-wear properties, can form a protective film on the mechanical friction surface, reduce wear and friction, and improve mechanical efficiency and life.

Classification of oil-soluble organic molybdenum additives

Common oil-soluble organic molybdenum compounds include dialkyl dithiophosphate molybdenum oxide (MoDTP), dialkyl dithiocarbamate molybdenum (MoDTC), etc. UNPChemicals focuses on the application and development of special lubricant additives. As the world's third supplier of liquid oil-soluble organic molybdenum friction modifiers, we provide high-quality MoDTP and MoDTC.

MSAIL® 300L: Molybdenum Dithiophosphate (MoDTP) as a liquid organic molybdenum friction modifier containing sulfur and phosphorus, it can greatly reduce the friction coefficient of oil products, and has multiple functions such as extreme pressure, anti-wear and anti-oxidation. It is widely used in internal-combustion engine oil, various industrial lubricants, pure oil metalworking fluid, grease, etc.

MSAIL® 525A/B: Molybdenum Dithiocarbamate (MoDTC) is a phosphate-free liquid organic molybdenum friction modifier, which can greatly reduce the friction coefficient of oil products, and has a variety of functions such as anti-wear and anti-oxygen, and is widely used in internal combustion engine oil, various industrial lubricants, pure oil-type metal working fluids, greases, etc.

Oil-soluble organic molybdenum additives - the older they get, the more spirited they are

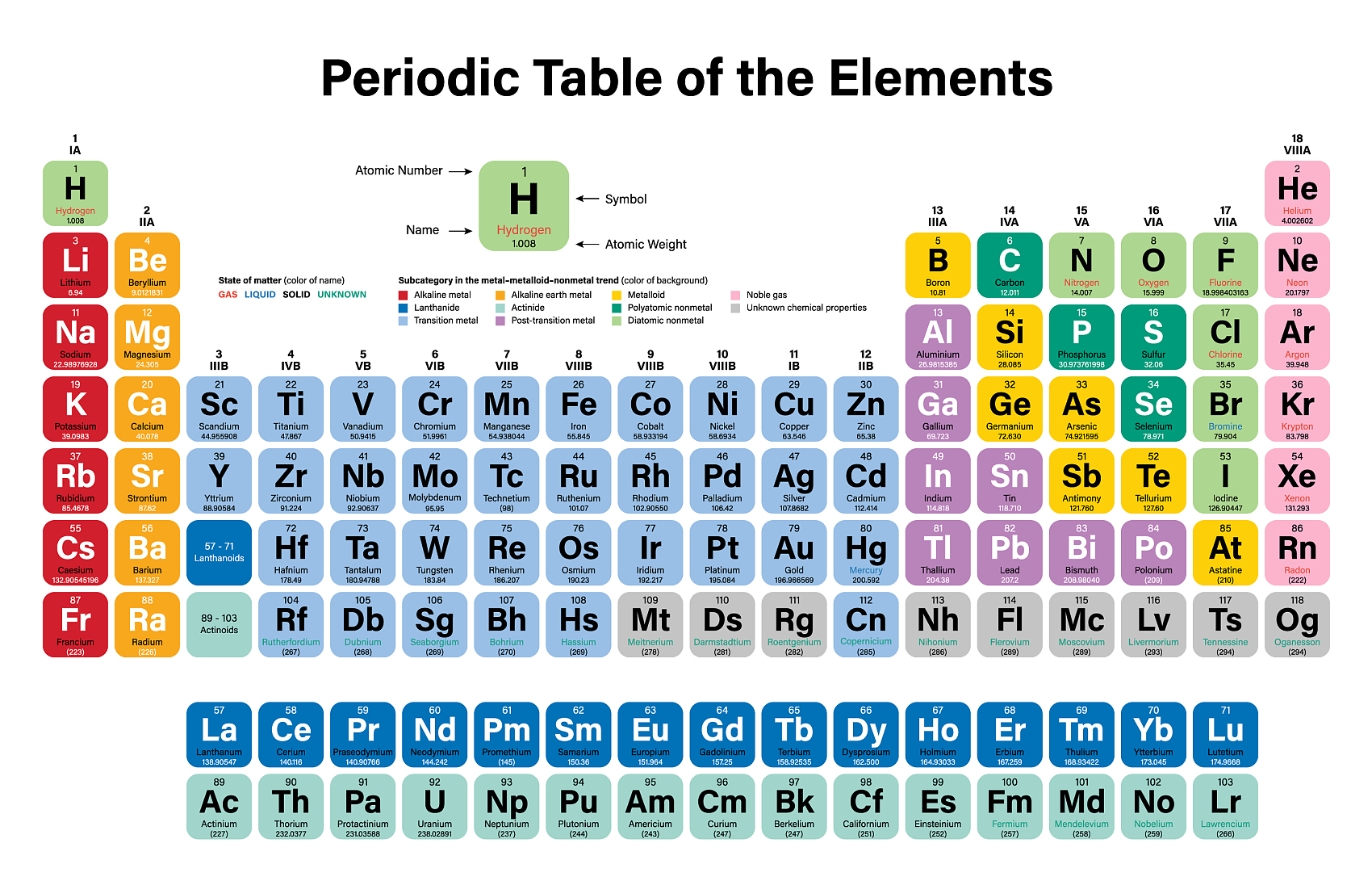

In the field of additives, we have talked about many metals, such as Zn, Ca, and Mg; we have also talked about many non-metals, such as S, P, Cl, N, and even O. In the field of anti-foaming agents, there is even Si. But the Mo (molybdenum) we are going to talk about today can be said to be a very magical existence. First of all, it is a transition metal. Although it is also called a metal, this guy is completely unlike a metal in many fields. Mo, the 42nd chemical element, is a trace metal element that the human body also needs. There are many substances in nature that contain molybdenum, such as chrysanthemum, pork, and eggs, but obviously these molybdenums are not on the same channel as the molybdenum we are talking about. But what I want to express is that everyone should not imagine it as a metal. This is very important.

The molybdenum friction modifier we are going to talk about today is the most typical example.

The earliest use in the industry was molybdenum disulfide powder, which was used in grease for about 80 or 90 years. The purpose was to reduce friction. However, due to the great difference between grease and lubricating oil, it has never been used in lubricating oil because of solubility and dispersibility. Later, scientists came up with a way to graft metal molybdenum into oil molecules, so that organic molybdenum appeared in the 1980s.

At present, the development of organic molybdenum is mainly related to the fuel economy of engine oil, and it is also the main driving force for the development of the organic molybdenum industry. Therefore, let's mainly talk about organic molybdenum in engine oil.

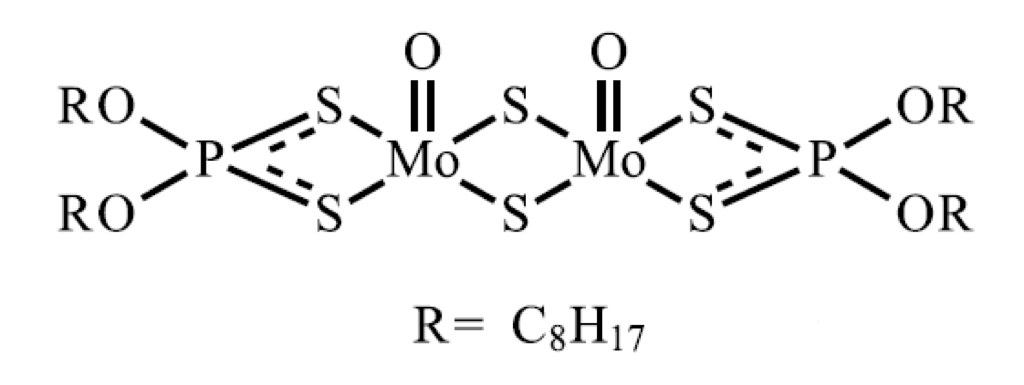

The earliest organic molybdenum is MoDDP, also called MoDTP, as shown below:

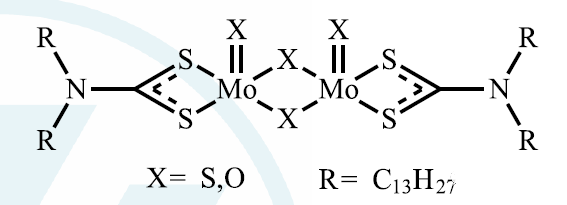

This structure is relatively simple, which is to replace the zinc element in ZDDP with molybdenum to reduce friction characteristics. There is no change in other elements. S and P are still there. It still has the functions of anti-oxidation and anti-wear. It is not bad, but it seems a bit out of place under the general trend of low SAPS. Therefore, MoDTC is available, which has less S and no P, as shown in the following figure:

Considering the core role of P, without P, its anti-wear performance is really not very good. We can only bring back the N element again to make up for the lack of S and P. Again, the core of the future will be N. There is a saying in Buddhism that there are three Buddhas. The Buddha in the past was S, the Buddha now is P, and the Buddha in the future will be N. In addition, MoDTC has some dissolution problems, which is also a difficult problem, but after decades of development, these have been gradually solved. But there is still sulfur. In order to completely solve it, it is necessary to completely avoid the idea of active sulfur. At this time, non-sulfur-phosphorus organic molybdenum powder comes on the scene, but what if there is no sulfur? What if there is no P? Can N alone take on this task? We will talk about it later. However, this path is correct. In order to improve the anti-wear performance in the future, we can also introduce the B element, which is still piling up bricks. These paths are the historical evolution of organic molybdenum. This article will not consider non-sulfur-phosphorus organic molybdenum for the time being, and will look at traditional programs first.

Okay, let's look at the principle, which is both simple and complex. That is, after Mo itself is introduced into the additive system, the Mo element itself has no ability. The key is to form a substance such as MoS2 as a friction film, which is the key to reducing friction. But how this friction layer is formed is still unclear. The only thing that can be determined is that the substance MOS2, which is about 10-40 nanometers wide and 1 nanometer thick, plays a role in reducing friction. It should also be noted that if the additive system does not contain S, then it will be difficult for molybdenum-containing additives to achieve the effect of reducing friction, because without the assistance of S elements, the friction film is difficult to achieve. At present, everyone will see that a single Mo-containing additive often does not become the core main agent. It is said to be complicated because in the current situation where various inspection and testing equipment are flying all over the sky, how this MoS2 is formed is still a mystery, especially how it is formed in the actual working conditions of the engine. People are keen on research, but it seems that no conclusive evidence can be produced. Of course, the friction film is not just a single substance like MoS2, there are other substances, but I omitted them for your understanding.

Although the principle is not clear, the role of organic molybdenum in reducing friction is unquestionable. A large number of tests and various evidences have proved the following eight words, "It is indeed effective, not a bluff". It has been almost half a century since it came out, but many ordinary people may still think it is a bit like a bluff, which is normal, "Practice is the only criterion for testing the truth".

It takes a certain amount of time for organic molybdenum to form MoS2 and then adhere to the boundary lubrication friction surface, especially to form a friction film on the rough friction surface layer. Therefore, most organic molybdenum will cause a sudden decrease in friction coefficient after a period of use. At this time, the Mo-containing additive forms a film on the surface and significantly reduces friction; and this MOS2-containing agent forms a stable friction layer on the surface, and the friction coefficient will also be maintained at a certain level. The Mo required for the friction surface has a certain capacity, that is, adding more will not have a greater effect, so the amount of Mo added is generally 20-1000ppm. Using the example of bread, flour is added under the action of water, and multiple layers of bread are directly generated. Don’t say that MoS2 is really layered.

MoDTP is a multifunctional additive for anti-oxidation, anti-wear, and friction reduction. The effect is very good, but the key is that it is the base of ZDDP and contains a higher P content, while MoDTC is actually more focused on reducing friction. So there are strengths and weaknesses.

Several key questions:

Why is the energy-saving effect good but the lifespan short?

Molybdenum-containing compounds, especially MoDTC, will oxidize the friction layer MoS2 into a stronger oxidation product MoO3 after the temperature rises or in a harsh high-temperature environment. At the same time, MoDTC itself is also a type of auxiliary antioxidant. Under excessively high conditions, Mo itself will join the team of antioxidants instead of acting as a friction modifier. Knowing this, we can protect MoDTC and try not to let it participate in auxiliary antioxidants, and leave this part of the work to other antioxidants. MoDTC will be free to concentrate on friction. Why do Japanese cars like Mo? This is completely in line with the design concept of Japanese cars. The design temperature is low, and Mo additives can show their prowess, which is completely contrary to German cars (German temperatures are high and fuel economy is not considered). Therefore, the internal causes of any external results you see are all technically logical, rather than just choosing Mo on impulse. So when you see the majority of enthusiasts on the AiKa forum, they pursue high performance on the one hand, and add MoDTC on the other hand, and then run it at high horsepower every day, then I don’t understand what the logic is. Instead of doing this, it is better to add ZDDP directly.

For MoDTC, its best friction reduction effect is for new oil. As the oil ages, Mo gradually loses, and the fuel economy effect is greatly reduced, that is, the long-term effect becomes worse. There are several solutions. One is to continue to add it, so that the MoS2 friction layer can continue to work, and the other is to replace it with a higher molybdenum amine, which we will talk about later.

The second big problem is that the MoS2 membrane is a very magical membrane. It has been verified that the interaction between MoDTC itself and ZDDP is very strong. The effect of mixing MoDTC and ZDDP is much higher than that of using them separately, and they promote each other. The principle is that ZDDP provides S elements, auxiliary antioxidants to protect MoDTC, and even provides a carrier for the membrane. It can be said that the auxiliary effect of ZDDP makes the effect of MoDTC amplified several times, just like the seven Quanzhen disciples fighting alone can not beat the East Evil, but when the Tiangang Beidou formation is set, the power is different; this is the synergistic effect of different additives. Mo is flour, and ZDDP is water.

At present, many vehicles like to consider adding DLC coatings, the purpose is also to reduce friction, and some manufacturers like to use some so-called ceramic parts (don’t know how to think about the Japanese ceramic knives), and the magic of MoS2 formed by MoDTC is that not only metal elements such as iron can form friction layers, but molybdenum layers can also form films on the surfaces of these substances, which means that the friction surface does not significantly affect molybdenum like other additives, which is entirely the ability of the additives themselves. In simple terms, "I am also a metal, I am not a polar end, I don't live on you, I just come to help you achieve wear reduction, whether you like it or not is none of my business", what's more, we said earlier that ZDDP will form an anti-wear film of zinc phosphate, and the molybdenum layer can continue to form a film on its surface, the so-called "film on film", my God, isn't it amazing! This also proves from another perspective that this multilayer film of MoS2 is more like a physically adsorbed film, which is also critical.

According to this logic, the main driving force for wear reduction is brought by Mo metal, and the mother body it grafted should theoretically have no effect, but there are relatively few studies in this area, but it is similar to the asymmetric principle of esters, that is, the R at both ends is different alkyl, and the wear reduction effect it provides will be better. Of course, if there is an egg on both sides, the effect will be better. This is the so-called amine branch chain technology, and some companies have expertise in it.

Nothing is good at everything. MoDTP and MoDTC are good at anti-wear, anti-oxidation and friction reduction. The most common shortcomings are solubility and corrosion. There are several reasons for corrosion. One is the activity control of sulfur elements and the other is the free amine after oxidation. Both are metal killers. Therefore, if you want to use this, you need to do a matching test in advance to ensure that there is no abnormality, or block it by adding corrosion inhibitors. Some people are also worried about the problem of high-temperature cleanliness, which is not the most important, because Mo is not a heavy metal, it is just a transition metal, it does not have such a strong influence, and there are also small problems such as high cost and dark color.

Using people, using their strengths and covering their weaknesses is the highest level of management. Mo has been standing in the industry for decades due to its excellent friction reduction effect!