The Relationship between Lubrication and Friction-The Role of MoDTC in Lubricating Oil

What is Tribology?

Tribology, as the name suggests, is a discipline that studies surface friction. It focuses on the friction, lubrication, and wear between the interacting surfaces in relative motion. Tribology has played a huge role in the progress of human civilization. In primitive society, the invention of fire by friction (drilling wood to make fire) by the clan marked the beginning of human civilization. The appearance of sledges around 9000 BC and the emergence of carts in China around 4600 BC, which replaced sliding friction with rolling friction, enabled humans to break away from the primitive living mode.

With the advancement of science and technology, there are currently two main ways to reduce friction:

Lubrication;

Applying coatings or surface treatments to mechanical parts to reduce the friction coefficient and wear.

The Relationship between Lubrication and Friction

Lubrication means adding a lubricant between two objects in relative motion to isolate the friction pair with an oil film, reduce the frictional resistance, and decrease wear.

The lubrication states between the surfaces of mechanical friction pairs can be divided into the following five types based on the formation mechanism and characteristics of the lubricating film:

1.Hydrodynamic lubrication;

2.Elastohydrodynamic lubrication;

3. Hydrostatic lubrication;

4. Boundary lubrication;

5. Unlubricated or dry friction state.

What is MoDTC?

MoDTC stands for molybdenum dialkyldithiocarbamate. It is a significant chemical compound in the field of lubrication. As an important additive in lubricating oil, it plays a crucial role in improving the performance of lubricants. It consists of molybdenum along with specific organic groups and sulfur-containing components. In the lubrication system, it participates in various physical and chemical processes during the operation of mechanical parts to help reduce friction and wear, thereby enhancing the overall efficiency and lifespan of the equipment.

The Role of MoDTC in Lubricating Oil

Lubricating oil is composed of base oil and additives. The main types of additives include dispersants, detergents, viscosity index improvers, and friction modifiers, etc. As a friction modifier, molybdenum dialkyldithiocarbamate (MoDTC) has emerged as a rising star in recent years. It has a high content of molybdenum and sulfur elements. It can not only increase the load-carrying capacity but also improve fuel economy, which is a major concern at present. It is an excellent multifunctional additive with high-temperature resistance, low corrosion, anti-oxidation, anti-wear, and friction reduction properties.

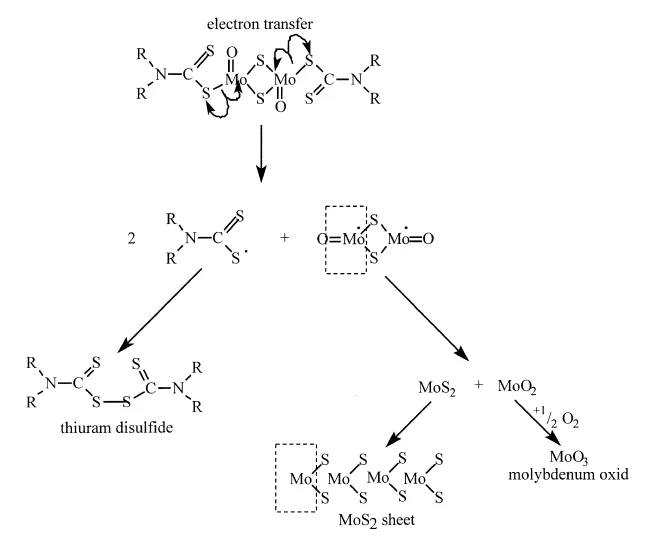

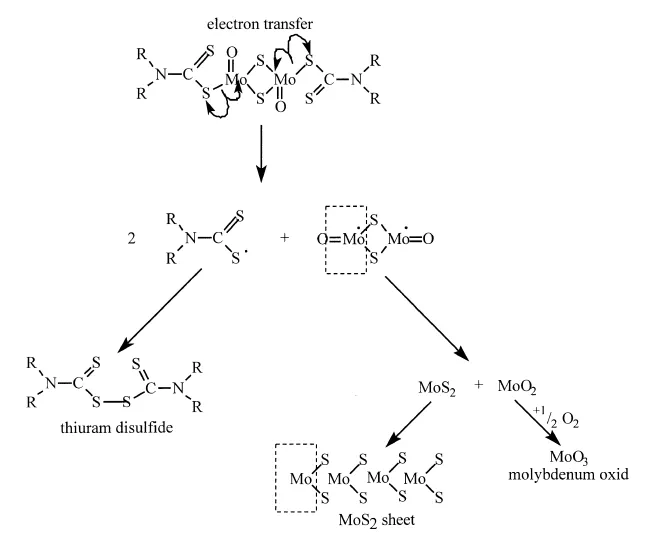

The Mechanism of MoDTC

MoDTC→MoS₂. Organic molybdenum is usually dissolved in the lubricant in a liquid form. During the friction process, it can form a physicochemical adsorption film with anti-friction and anti-wear effects on the friction surface. Studies have shown that MoDTC has the best friction reduction effect at 250°C, loses its anti-wear effect at 320°C, and generates a higher content of MoS₂ at 125°C, resulting in better anti-friction and anti-wear properties. The recommended addition amount is usually 0.5% - 1.0%. It does not contain phosphorus, which reduces the poisoning of automotive exhaust purifiers. It has stable chemical properties and is easy to decompose at high temperatures. Therefore, the anti-wear and friction reduction performance of MoDTC is more prominent under high-temperature conditions.

Features of MoDTC

Friction and Wear Reduction: MoDTC is well-known for its excellent ability to reduce friction between moving surfaces. It forms a protective film on the friction surfaces during the friction process. This film can effectively separate the contact surfaces to a certain extent, minimizing direct contact and reducing the frictional resistance. As a result, it significantly decreases the wear of mechanical components, making them more durable and less prone to damage caused by friction.

High-Temperature Performance: It exhibits remarkable performance under high-temperature conditions. As the temperature rises, it can still maintain its stability to some degree and continue to play its role in reducing friction and wear. In particular, at relatively high temperatures within its applicable range, its anti-wear and friction reduction properties become even more prominent compared to some other additives, which enables it to meet the lubrication requirements of high-temperature operating machinery.

Fuel Economy Improvement: One of the notable features is its contribution to improving fuel economy. By reducing the frictional losses in engines and other mechanical systems, it helps the equipment to operate more smoothly and with less energy consumption. This, in turn, leads to better fuel utilization and ultimately results in savings in fuel costs, which is of great importance in modern transportation and industrial applications.

Chemical Stability: MoDTC has relatively good chemical stability. It can coexist stably with other components in the lubricating oil and is not easily affected by external chemical factors in normal usage environments. This stability ensures that it can continuously exert its functions over a long period and maintain the quality and performance of the lubricant without undergoing unexpected chemical reactions that could undermine its effectiveness.

Low Corrosion: It shows low corrosive properties towards the metal surfaces of mechanical parts. Unlike some additives that might cause corrosion or damage to the metal over time, MoDTC can protect the metal surfaces while reducing friction, which is beneficial for maintaining the integrity and performance of the mechanical components and prolonging their service life.

Absence of Phosphorus: Another important feature is that it does not contain phosphorus. This is significant because in automotive applications, for example, the absence of phosphorus reduces the risk of poisoning the automotive exhaust purifiers. It helps to meet the strict environmental requirements and allows for better compatibility with modern vehicle emission control systems.

The Synthesis Technologies of MoDTC

There are mainly three synthesis technologies for MoDTC:

1.Preparation method of solid MoDTC (lower alkane organic molybdenum is solid) This method uses two ways to dissolve MoO₃ as the molybdenum source. (a) Dissolve MoO₃ with ammonia water or sodium hydroxide. After neutralizing with acid to neutrality, add diisooctylamine and CS₂, and heat to a certain temperature for reaction to obtain the product. (b) Dissolve MoO₃ in diisooctylamine, then add diisooctylamine and CO₂, and heat to a certain temperature for reaction to obtain the product.

2.Preparation method of liquid MoDTC (alkanes with more than 12 carbons are liquid) MoDTC is prepared by dissolving the hexavalent molybdenum source with sodium hydrosulfide or sodium sulfide, and mixing with CO₂, diisooctylamine, mineral acid, and reducing agent. The advantages of this method are high product yield, low corrosiveness, good friction performance, and excellent lubrication characteristics.

3. Preparation method of MoDTC containing asymmetric alkyl groups The amine sources used are diisotridecylamine, isodecyloxypropylpropylamine, or C12 - C15 alkoxypropylisopropylamine (using different amine sources can produce MoDTC with different alkyl group characteristics). The advantage of this method is that MoDTC has better low-temperature oil solubility.

The Price of friction modifiers in lubricating oil additives

The price of friction modifiers in lubricating oil additives varies depending on factors such as brand, specification, composition, and sales channels. If you are interested in friction modifiers, please feel free to contact us.

Supplier of friction modifiers in lubricating oil additives

UNPChemicals is a professional supplier of high-quality and effective friction modifiers in lubricating oil additives. We offer several remarkable products, namely Molybdenum dithiophosphate MSAIL 300L MoDTP, Molybdenum dithiocarbamate MSAIL 525A MoDTC,Organomolybdenum complex S/P free MSAIL 8550 and Nitrogen-containing boric acid esters FMET 2890.

Molybdenum Dithiophosphate (MoDTP) MSAIL 300L as a liquid organic molybdenum friction modifier containing sulfur and phosphorus, it can greatly reduce the friction coefficient of oil products, and has multiple functions such as extreme pressure, anti-wear and anti-oxidation. It is widely used in internal-combustion engine oil, various industrial lubricants, pure oil metalworking fluid, grease, etc.

Molybdenum Dithiocarbamate MSAIL 525A MoDTC is a phosphate-free liquid organic molybdenum friction modifier, which can greatly reduce the friction coefficient of oil products, and has a variety of functions such as anti-wear and anti-oxygen, and is widely used in internal combustion engine oil, various industrial lubricants, pure oil-type metal working fluids, greases, etc.

Organomolybdenum complex (S/P free) MSAIL 8550 is a highly versatile and environmentally friendly lubricant additive belonging to the Organomolybdenum complex class. Its exceptional friction reduction properties, superior performance when combined with sulfur additives, and antioxidation synergism make it an ideal choice for a wide range of applications. Mainly used for internal-combustion engine oil, various industrial lubricating oils, pure oil metalworking fluid and lubricating grease.

Nitrogen-containing boric acid esters FMET 2890 is an ashless friction modifier that does not contain sulfur or phosphorus. It has excellent friction reduction, wear resistance, and corrosion inhibition performance. It is widely used in internal-combustion engine oil, various industrial lubricants, pure oil metalworking fluid, grease, etc.

Conclusion

Friction modifiers are crucial in lubricating oils. They modify frictional characteristics, have good characteristics to handle complex conditions and meet environmental needs, shine in boundary lubrication, are widely applied in multiple industries, and work with other properties to optimize lubrication and improve mechanical equipment's performance in different lubrication states.

UNPChemicals supplies various lubricating oil additives such as friction modifiers, metal deactivators, extreme pressure anti-wear agents and metal processing additives. If you're interested, please contact us.