Application of Anti-wear Hydraulic Oil Additive Package in Construction Machinery

Construction machinery, as a key equipment for modern construction, is widely used in many fields such as construction, mining, and ports. During its operation, the hydraulic system plays a crucial role. It is responsible for converting mechanical energy into hydraulic energy and realizing the transmission and control of power through the flow of hydraulic oil. Since construction machinery usually operates under harsh working conditions, such as high temperature, high pressure, high load, and a dusty environment, it poses extremely high requirements for hydraulic oil.

Hydraulic oil not only needs to have good lubricating performance to reduce the wear between various moving parts in the hydraulic system and extend the service life of the equipment. It also needs to have excellent anti-wear performance, being able to form an effective protective film under high load conditions to prevent direct contact between metal surfaces and the occurrence of wear. At the same time, it should also have stable chemical properties, maintaining performance stability under different temperatures and pressures, and resisting chemical reactions such as oxidation and hydrolysis to ensure the reliable operation of the hydraulic system. The anti-wear hydraulic oil additive package, as an additive specially developed to meet these stringent requirements, has been increasingly widely used in the field of construction machinery. It can significantly improve the comprehensive performance of hydraulic oil and provide a strong guarantee for the efficient and stable operation of construction machinery.

Application of Anti-wear Hydraulic Oil Additive Package in the Hydraulic System of Excavators

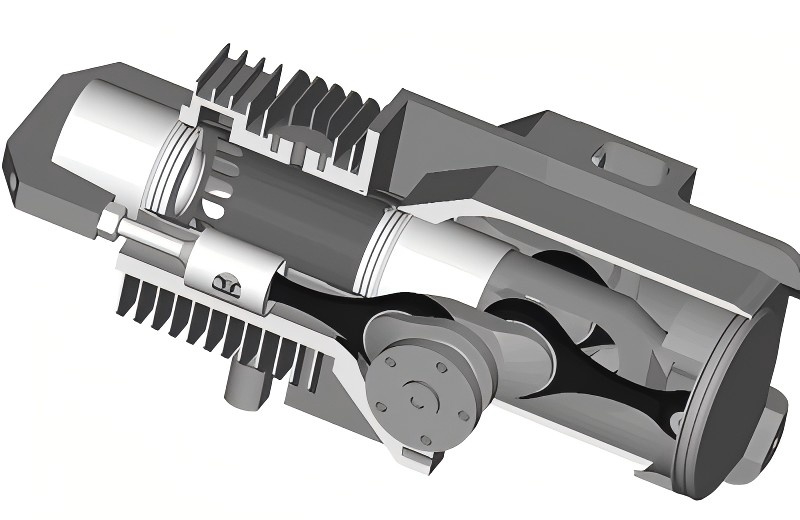

The excavator is one of the most widely used equipment in construction machinery. Its hydraulic system has high working pressure, frequent load changes, and often operates under harsh working conditions. During the operation of the excavator, the hydraulic oil needs to drive components such as hydraulic pumps, hydraulic cylinders, and hydraulic motors frequently. These components operate in a high-speed and high-pressure environment, imposing extremely high requirements on the anti-wear and lubricating performance of the hydraulic oil.

The anti-wear hydraulic oil additive package plays a key role in the hydraulic system of excavators. On the one hand, it can form a tough adsorption film and a chemical reaction film on the metal surface. When the plunger and cylinder block, as well as the valve plate of the hydraulic pump, and the piston and cylinder barrel of the hydraulic cylinder move relative to each other under high load, this protective film can effectively reduce the friction coefficient and the occurrence of wear. For example, in an excavator used in a large open-pit mine, before using the anti-wear hydraulic oil additive package, the plunger and cylinder block of the hydraulic pump needed to be repaired or replaced on average every three months. This not only increased the maintenance cost but also seriously affected the normal operation time of the equipment. After using the hydraulic oil added with the anti-wear hydraulic oil additive package, through continuous monitoring of high-intensity operation for six months, the wear situation of the hydraulic pump was significantly improved. The wear amount of the plunger and cylinder block was reduced by about 50%, and the maintenance cycle was extended to more than six months, greatly improving the reliability and working efficiency of the equipment.

On the other hand, the anti-wear hydraulic oil additive package can also enhance the oxidation resistance of the hydraulic oil. During long-term operation of the excavator, the hydraulic oil will be oxidized due to factors such as high temperature, high pressure, and metal catalysis, generating acidic substances, sludge, and other pollutants. These pollutants will further corrode the metal components of the hydraulic system and reduce the performance of the hydraulic oil. The antioxidant components in the additive package can effectively inhibit the oxidation reaction and extend the service life of the hydraulic oil. Through regular detection of the hydraulic oil of multiple excavators in this mine, it was found that the oxidation stability index of the hydraulic oil containing the anti-wear hydraulic oil additive package was significantly better than that of the hydraulic oil without the additive package. The oxidation induction period was extended by about 30%, effectively reducing the replacement frequency of the hydraulic oil and reducing the operation cost.

Performance of Anti-wear Hydraulic Oil Additive Package in the Hydraulic System of Loaders

Loaders are mainly used for operations such as loading, transporting, and unloading materials. Their hydraulic systems also face complex working conditions. When the loader is operating, the hydraulic system needs to frequently realize operations such as reversing and speed changing. The hydraulic oil needs to respond quickly and transmit power, and at the same time, it also needs to withstand a large impact load.

The anti-wear hydraulic oil additive package can significantly improve the performance of the hydraulic system of loaders. In terms of anti-wear performance, it can effectively deal with the impact load during the operation of the loader. When the loader's bucket inserts into the material pile, the hydraulic system instantly bears a huge pressure impact. At this time, the protective film formed by the anti-wear hydraulic oil additive package can quickly play a role in preventing key components such as the gears and vanes of the hydraulic pump and the piston rod of the hydraulic cylinder from being worn due to the impact. In a construction site, a batch of loaders were subjected to a comparative test. One group of loaders used ordinary hydraulic oil, and the other group used hydraulic oil added with the anti-wear hydraulic oil additive package. After one month of high-intensity operation, the inspection found that in the hydraulic system of the loaders using ordinary hydraulic oil, the wear of the gears of the hydraulic pump was relatively obvious, and there were certain degrees of scratches and spalling on the tooth surface. However, for the loaders using the hydraulic oil added with the additive package, the wear degree of the gears of the hydraulic pump was much lighter, the tooth surface was relatively smooth, and there were only slight wear marks. This fully demonstrates the remarkable effect of the anti-wear hydraulic oil additive package in improving the anti-impact wear resistance of the hydraulic system of loaders.

In terms of improving the low-temperature fluidity of the hydraulic oil, the anti-wear hydraulic oil additive package also plays an important role. For loaders operating in cold regions, the winter temperature is relatively low, and the viscosity of ordinary hydraulic oil will increase significantly, resulting in difficult startup of the hydraulic system and a slower response speed. However, the low-temperature fluidity of the hydraulic oil added with the additive package has been significantly improved. The pour point depressant component in the additive package can reduce the pour point of the hydraulic oil, enabling it to still maintain good fluidity in a low-temperature environment. Through practical application tests in a cold region in the north, when the outdoor temperature reaches -20°C in winter, the startup time of the hydraulic system of the loader using the hydraulic oil added with the anti-wear hydraulic oil additive package is about 30% shorter than that of the loader using ordinary hydraulic oil, and the system's response speed is faster. It can quickly realize actions such as lifting and turning of the bucket, greatly improving the operation efficiency of the loader in a low-temperature environment.

Case of Anti-wear Hydraulic Oil Additive Package in the Hydraulic System of Bulldozers

Bulldozers are commonly used for large-scale earthwork operations. Their working environment is harsh, and the hydraulic system needs to operate under high load and high pressure for a long time. During the earthmoving operation of the bulldozer, the hydraulic system needs to push a huge blade to cut the soil and frequently adjust the angle and height of the blade, which poses a great test to the performance of the hydraulic oil.

Take the bulldozers used in a large-scale water conservancy project construction as an example. The soil texture at the construction site of this project is hard, and the operation intensity is high, with a daily working time of more than 10 hours. When using ordinary hydraulic oil, the hydraulic system of the bulldozer frequently had failures. The piston rod of the hydraulic cylinder was severely worn, and the aging of the seals was accelerated, resulting in frequent hydraulic oil leakage. This not only affected the construction progress but also increased the maintenance cost. Later, the engineering team used the hydraulic oil added with the anti-wear hydraulic oil additive package. After a period of use, the effect was remarkable. The wear amount of the piston rod of the hydraulic cylinder was greatly reduced, the service life of the seals was extended by about 50%, and the hydraulic oil leakage phenomenon was effectively controlled. Through the disassembly and inspection of the key components of the hydraulic system, it was found that after adding the additive package, a uniform and firm protective film was formed on the surface of the piston rod, effectively resisting the wear of impurities such as soil particles and also reducing the erosion of the seals by the hydraulic oil, thus extending the service life of the seals.

In addition, the anti-wear hydraulic oil additive package can also improve the cleanliness of the hydraulic system of bulldozers. During earthwork operations, a large amount of dust and impurities easily enter the hydraulic system through the air filter and other channels, contaminating the hydraulic oil. The detergent-dispersant component in the additive package can disperse the pollutants into tiny particles, making them suspended in the hydraulic oil to avoid the deposition of sludge and paint film in the system, thus maintaining the cleanliness of the hydraulic system. Regular oil detection of the hydraulic system of the bulldozer using the hydraulic oil added with the anti-wear hydraulic oil additive package showed that the pollutant content in the hydraulic oil always remained at a low level, effectively ensuring the normal operation of the hydraulic system and reducing the probability of failures caused by oil contamination.

In conclusion, the anti-wear hydraulic oil additive package has demonstrated excellent performance and wide applicability in the hydraulic systems of the main equipment of construction machinery, such as excavators, loaders, and bulldozers. In the hydraulic system of excavators, it can effectively reduce the wear of key components, extend the maintenance cycle, and at the same time enhance the oxidation resistance of the hydraulic oil and extend the service life of the hydraulic oil. In the hydraulic system of loaders, it not only improves the anti-impact wear resistance but also improves the low-temperature fluidity of the hydraulic oil and enhances the operation efficiency of the equipment in a low-temperature environment. In the hydraulic system of bulldozers, it significantly reduces the wear of components such as the piston rod, extends the service life of the seals, and at the same time maintains the cleanliness of the hydraulic system and reduces the probability of failures.

With the continuous development of the construction machinery industry, the power and operation intensity of the equipment continue to increase, and the performance requirements for the hydraulic system are also getting higher and higher. As a key additive to improve the comprehensive performance of hydraulic oil, the anti-wear hydraulic oil additive package will play an even more important role in the field of construction machinery. It can not only improve the reliability and working efficiency of the equipment, reduce the maintenance cost but also reduce the downtime of the equipment, providing strong support for the smooth progress of engineering construction. Therefore, further promoting and applying the anti-wear hydraulic oil additive package is of great significance for promoting the efficient and sustainable development of the construction machinery industry. In the future, with the continuous progress of technology, the performance of the anti-wear hydraulic oil additive package will continue to be optimized and improved, and it is expected to bring more value and innovative development opportunities to the construction machinery industry.

The Price of Hydraulic Oil Additives Package

The price of Hydraulic Oil Additives Package varies depending on factors such as brand, specification, composition, and sales channels. If you are interested in Hydraulic Oil Additives Package, please feel free to contact us.

Supplier of Hydraulic Oil Additives Package

UNPChemicals is a professional supplier of high-quality and effective Hydraulic Oil Additives Package. We offer several remarkable products, namely High zinc hydraulic oil additives UNP AH502A,Low Zinc Hydraulic Oil Additives UNP AH502B,Zinc-free Hydraulic Oil Additives UNP AH502C,etc.

High zinc hydraulic oil additives UNP AH502A are a type of chemical additive used in hydraulic oils that contain high levels of zinc dialkyldithiophosphate (ZDDP). ZDDP is a well-known anti-wear agent that also provides antioxidant, anti-corrosion, and anti-foam properties. The zinc in these additives plays a crucial role in forming a protective film on metal surfaces within the hydraulic system, thereby reducing wear and extending the life of the system components.

Low Zinc Hydraulic Oil Additives UNP AH502B are a class of advanced lubricant additives designed to enhance the performance of hydraulic oils with reduced zinc content.These additives are formulated to provide a balance of anti-wear,extreme pressure,and antioxidant properties,making them suitable for modern hydraulic systems that demand high performance with lower environmental impact.

Zinc-free Hydraulic Oil Additives UNP AH502C are a new class of environmentally friendly lubricant additives designed for hydraulic systems.These additives are formulated to provide the same level of performance as traditional zinc-containing additives but without the heavy metal content,reducing the environmental impact of hydraulic fluids.

Professional Lubricant Additive Manufacturer

UNPChemicals,aka Luoyang Pacific United Petrochemical Co., Ltd., focuses on the application and development of special lubricating grease additives such as MODTC, MODTP, molybdenum amide, thiadiazole metal deactivators, and phosphate esters. With nearly 30 products in seven series, including extreme pressure anti-wear additives and special grease additives, it is a global manufacturer of special lubricating grease additives and a national high-tech enterprise with great influence and leading role in the industry. If you are looking for Lubricant Additive or technical information, feel free to contact UNPChemicals.